Ejector Pins Manufacturers & Suppliers In India.

EJECTOR PINS MANUFACTURERS & SUPPLIERS IN INDIA

Ejector Pins Information-

Ejector pins are one of the essential parts in the industry of injection molding. These long pins, generally made of fine quality steel i.e. EN-31, H-13(SKD 61) and HSS(M2) are used for forcefully pushing the molded items out of the molds. Often known as knockout pins, these pins are the cheapest and best means of ejecting the solid molded products out of the mold cavities.

Straight Ejector Pin-

Straight Ejector Pins, made from the finest quality of die steel i.e EN-31, H-13(SKD 61) and HSS(M2) are one of the essential components for manufacturing molded products. The heads of the straight ejector pins are hot forged and the stress relieved for ensuring its high tolerance and standard surface finish. These pins are made utilizing the latest technology that bestows them with exact and proper specifications.

Depending on the machines with various capacity and different working specifications, you can choose among the diameters of 1 to 20 and the length of 50 mm to 500 mm, provided by the best straight ejector pin manufacturers. In case the mentioned measurement does not suit the purpose, the customizing option is always available.

While the core is stiffened to 44- 52 HRC, the majority of the straight ejector pins comes with a nitride coating (65- 75 HRC) that is applied in a proprietary process. It is this process that gives these pins long life and toughness, by creating a layer of diffusion between the softer core and the hardened outer coating.

Competent Engineers is one of the most trusted and reputed straight ejector pin manufacturers that provide a wide variety of straight knockout pins, both in lengths and diameters. Having an extensive industrial use, these pins come with extreme durability.

Diagram

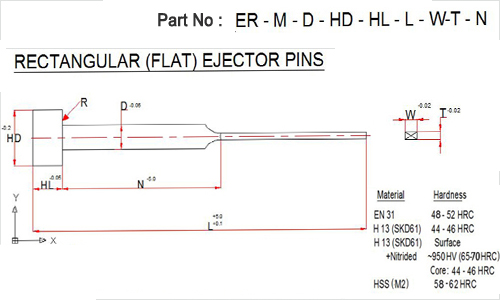

Rectangular(Blade) Ejector Pin-

Stepped Ejector Pin-

Just like the other Ejector Pins, the stepped long pins also come with strong propertie like Corrosion resistance, Heat durability and Tensile strength.

Though the tolerance capacity varies depending on the diameter of the tip of these pins; the high-quality metal used in manufacturing these mould pins ensures their best performance. While the core or the base material of some of these pins are hardened to 45 - 48 HRC; some are stiffened to almost 58 - 62 HRC Some pins even coming with a nitride surface, possesses maximum outer coating strength.

A quality step ejector pin, provided by the best stepped ejector pin manufacturers, should be capable of ejecting the molded products from the molds flawlessly, irrespective of whether the molded product is alloyed or plastic. Made by the highest grade metals, these pins serve their main purpose of taking out the molded product effortlessly, after its solidification.

- One Stepped Ejector Pin

- Two Stepped Ejector Pin

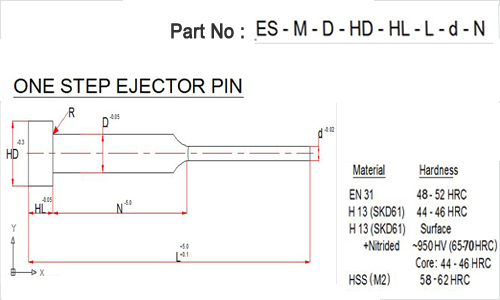

One Stepped Ejector Pin-

The use of one stepped ejector pin is huge in the industry of injection mould. Based on the needs of various molded products and different machines, there is always a tremendous need for this particular type of ejector pins in the market.

Often referred to as a shoulder push pin, this pin is used mainly to give the narrow part of the ejector pin the required strength when it is ejected. This pin also helps to strengthen to ejector pin when a straight type may get bend during the process of ejecting. Coming in different dimensions and specifications, this pin caters to the various needs of the molding industry.

Diagram

Two Stepped Ejector Pin-

Two stepped ejector pin is known to be one of the most significant parts among the various injection mould accessories. Made with the finest quality material, the unique shape of this pin is meant to cater to the various molding requirements of the injection moulding industry.

Being available in different sizes and dimensions, this pin exhibits qualities such as corrosion resistance, heat tolerance and tensile strength, which makes it ideal for using in ejecting solid molded products out of their mould cavities. Helping to reduce the needed for fitting by possessing a precision tolerance diameter, this pin helps in performing a non-galling operation, that also very smoothly.

Comments

Post a Comment